Note: This project reflects the kind of work that only becomes possible at the intersection of AI capability and domain expertise. The process involved multiple iterations, countless adjustments, and detailed inputs on everything from shotgun shell behavior to mechanical feed tolerances. I provided photos, reference schematics, vendor considerations, and numerous corrections as the design evolved. None of it could have been built by simply prompting an AI — it required applied knowledge of shotguns, shotshell ballistics, recoil management, and practical gunsmithing experience to guide the system toward something real, functional, and field-serviceable. AI dramatically accelerated the drafting, organizing, and refining of the concept, but it was my subject matter experience that allowed the system to converge on a workable design.I’m telling you this because MIT just released a study that essentially says AI is making us dumber. But the fine print is important: if you start without AI—like I do—by building your thesis and doing baseline research first, and then use AI as a research assistant, it actually improves performance.

It is important to note that this is a concept. Not something ready to send to Dillon in Arizona. It is, however, a very sound concept. In fact, if I wanted to market it my tag line would be: What Delivers 22,000 Tungsten Projectiles Per Minute into a Meter-Wide Kill Zone? Pure marketing hype. But cyclic rate is often expressed in rounds per minute.

Gimbal-Mounted Electric Shotgun Gatling: C-UAS Concept Development

The system is an electrically driven, low-speed, cam-operated Gatling-style shotgun, specifically engineered for small counter-unmanned aerial systems (C-UAS) defense. Mounted on a stabilized 2-axis gimbal, it combines mechanical simplicity with extreme tolerance for feeding errors, shell deformation, and real-world field conditions. The design focuses on defeating small UAV threats at ranges of 40 to 60 meters.

At its core, the weapon employs a traditional Gatling rotary principle, but adapted for shotshell operation. Instead of relying on complex feed belts or link systems, it utilizes a spring-loaded hopper or drum magazine-fed, cam-indexed feeding mechanism capable of handling 3-inch and 3.5-inch 12-gauge shells. The system is highly forgiving of shell length variations, minor hull deformations, or skipped feed cycles, automatically advancing without causing stoppages. This approach significantly reduces the mechanical complexity typically associated with fully automatic shotguns or multi-barrel weapon systems.

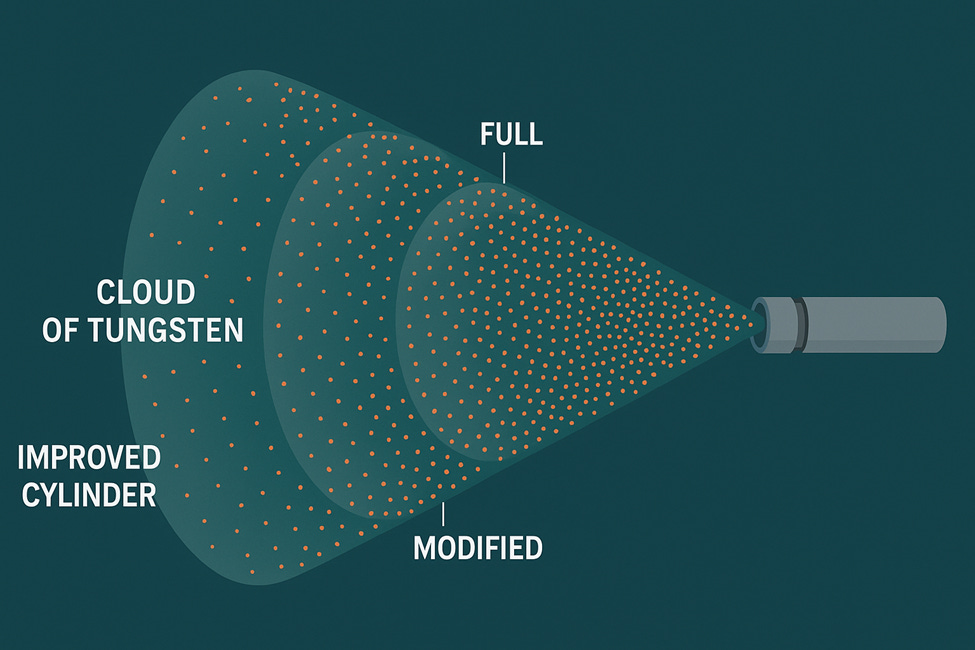

The barrels form a rotating cluster of either five or six smoothbore tubes, each approximately 18 to 20 inches in length. Where the design becomes particularly innovative is in the use of fixed, variable chokes across the barrels. Unlike a conventional shotgun firing a single, uniform shot pattern, this system layers shot dispersion across its full rotational cycle. Some barrels are set to tighter constrictions (such as Full choke, ~0.035"), while others are configured more openly (Improved Cylinder ~0.010"). This deliberate variation creates a forward-projecting "cloud" of shot that combines dense central patterns with wider peripheral coverage.

In practical terms, consider a six-barrel array. Barrel one might employ Full choke, barrel two Modified, barrel three Improved Cylinder, barrel four Modified again, barrel five Cylinder (open), and barrel six returning to Full. As each barrel fires in sequence, milliseconds apart, the resulting pellet distribution forms a layered cone of increasing spread. At typical C-UAS engagement ranges of 40 to 60 meters, this configuration produces a dense core approximately 18 to 24 inches wide, surrounded by layers that gradually widen to as much as 50 inches depending on choke. The result is not a flat wall of shot, but rather a dynamic, coherent cloud that offers both precision for stable targets and margin for drones executing erratic movements.

Hate Subscriptions? Me too! You can support me with a one time contribution to my research at Buy Me a Coffee. https://buymeacoffee.com/researchukraine

The drive system uses an electric motor with a worm gear and cam cycle reminiscent of early Gatling designs, but modernized for industrial reliability. Torque requirements fall between 4 to 8 Nm, with continuous power demands of 400 to 700 watts on either 24VDC or 48VDC supplies. Components from established motion control vendors such as Maxon, Kollmorgen, Moog, or Oriental Motor would be appropriate for prototyping. The system runs at a deliberately slow cyclic rate of 3 to 6 rounds per second (180–360 RPM), allowing the gimbal to fully recover between shots while minimizing vibration and wear.

Recoil management is a critical aspect of the design. Each shot may generate recoil forces up to ~60 ft-lb using 3.5” magnum shells. However, the rotating nature of the barrel cluster distributes recoil events sequentially, reducing peak impulse transmitted to the gimbal. Additional damping is provided through spring or hydraulic buffer assemblies integrated directly into the gimbal mount, drawing on commercial systems from suppliers like Taylor Devices and ACE Controls.

The gimbal itself provides full 360-degree azimuth coverage and elevation ranging from +80° to -20°. Servo-controlled with roughly 40 to 50 Nm of torque capacity per axis, it operates comfortably within a total system power envelope of 600 to 1000 watts. Vendors such as Harmonic Drive, L3Harris, Moog, and BAE Systems provide commercial gimbal systems well-suited for this application.

Physically, the complete system maintains a compact footprint, requiring roughly 36 inches by 36 inches of mounting area and weighing between 150 to 200 pounds including the gimbal, gun assembly, motor, and feed system. The ammunition supply is housed in a reloadable spring-loaded hopper or drum magazine with capacity for 100 to 200 shells.

Importantly, the system is designed for field serviceability. The mechanical architecture allows full inspection and disassembly with minimal specialized tooling. There are no complex electronics embedded within the gun itself; all advanced fire control is slaved externally to existing sensor packages. This simplifies integration into a wide variety of C-UAS platforms without heavy redesign of host systems.

In reliability terms, the cam cycle tolerates nearly all common failure modes for shotshell weapons, including misfeeds, soft chambering, or partial shell deformation. Failed load cycles simply advance without jamming, and spent shells are automatically extracted.

As development proceeds, subsystem sourcing has already been modeled. The key modules include the rotary drive and cam system, feed system, gimbal platform, recoil buffering, and structural materials. CNC billet aluminum or aircraft-grade alloys form the core chassis, with nitrided or chrome-lined barrels ensuring durability against high-density tungsten or bismuth loads. Integrated choke inserts will be machined directly into each barrel for long-term consistency.

Integration and Limitations

This system solves one very specific problem: how to shoot down a small drone once you know exactly where it is. But by itself, it cannot find targets, track them, or decide when to fire. It has no sensors or radar built in. Without help from other systems that can detect, identify, and track drones in real time, this weapon has nothing to aim at.

This weapon must operate as part of a broader defensive architecture that includes radar, electro-optical and infrared sensors, acoustic detection, and real-time target classification algorithms. External sensor nodes must provide both azimuth and elevation targeting data, as well as fire-permission logic, to ensure safe and effective engagement. Targeting errors, false positives, or late cues could either render the system ineffective or risk unintended engagements.

Additionally, while the layered shot cloud increases hit probability against evasive or fast-moving drones, the effective engagement envelope remains limited to relatively short ranges of 40 to 60 meters. This requires that detection and handoff occur rapidly enough to bring the target into that constrained engagement zone.

The system’s strength is in its simplicity, reliability, and devastating short-range firepower. Its weakness is that it is entirely dependent on external systems to see, think, and decide. In modern C-UAS defense, this kind of specialized weapon is most effective as one node within a fully integrated kill chain.

Technical Data Summary Index

Platform Type

● Electrically driven Gatling rotary shotgun

Intended Use

● Counter-UAS, vehicle-mounted or fixed-site defense

Drive System

● Electric motor with worm gear and cam-operated cycling

● 4–8 Nm continuous torque

● 400–700 watts continuous power

● 24VDC or 48VDC supply

Fire Control

● Slaved to external targeting system (sensor node provides aimpoint)

Chamber & Ammunition

● 12-gauge shotshells, 3-inch and 3.5-inch

● Tungsten shot, bismuth shot, frangible anti-drone rounds

● Shot sizes supported: #4 Buck through BB shot

Feeding System

● Spring-loaded hopper or drum magazine-fed rotary indexing

● Capacity: 100–200 shells

● Highly tolerant of shell length variances and hull deformation

● Misfeeds automatically skipped

Barrel Assembly

● 5 or 6 rotating barrels

● Smoothbore, 18–20 inch length

● Fixed chokes per barrel: Full, Modified, Improved Cylinder, Cylinder

● Choke values: Full (~0.035"), Improved Cylinder (~0.010")

Cycle Speed

● 3–6 rounds per second (180–360 RPM full rotation)

● Barrel dwell: ~60° per firing cycle for 6-barrel design

Recoil Management

● Maximum impulse: ~60 ft-lb per shot

● Distributed recoil through barrel rotation

● Spring or hydraulic dampers with servo compensation

Gimbal System

● 2-axis (azimuth + elevation)

● Azimuth: 360° continuous rotation

● Elevation: +80° to -20°

● Torque Capacity: 40–50 Nm per axis

● Peak Power Draw: 600–1000 watts total

● Servo-controlled, external fire control input

System Size & Weight

● Mount footprint: ~36” x 36”

● Full system weight: 150–200 lb (gun, gimbal, motor, feed)

● Ammo reserve: 100–200 shells

Failure Modes & Reliability

● Cam cycle tolerant of misfeeds, incomplete chambering, soft hull deformation

● Failed load cycles skip and advance automatically

● Spent shells auto-extracted

Maintenance & Serviceability

● Open mechanical design

● Field strip and inspection

● Minimal specialized tools

● Operator-level service

● Designed for real-world field environments

Materials & Structure

● CNC billet aluminum or aircraft alloy frame

● Nitrided/chrome-lined barrels

● Integrated variable choke inserts

Vendors & Components (Phase 2 Modeling)

● Motors: Maxon, Kollmorgen, Oriental Motor, Moog

● Gimbals: Harmonic Drive, Moog, Kollmorgen, BAE, L3Harris

● Recoil Buffers: Taylor Devices, ACE Controls

● Feed system: CNC machine shops, shotgun mag suppliers

Animation of Dillon Aero:

Benjamin Cook continues to travel to, often lives in, and works in Ukraine, a connection spanning more than 14 years. He holds an MA in International Security and Conflict Studies from Dublin City University and has consulted with journalists and intelligence professionals on AI in drones, U.S. military technology, and open-source intelligence (OSINT) related to the war in Ukraine. He is co-founder of the nonprofit UAO, working in southern Ukraine. You can find Mr. Cook between Odesa, Ukraine; Charleston, South Carolina; and Tucson, Arizona.

Mr. Cook’s Substack:

Ben: NOT FAIR!!!!! The stupid ducks do not stand a chance. Man you are SO CRUEL. You are gonna cause the extinction of Russian water fowl.

:o)~

Sounds like a re-hash of the defunct Australian "metal storm" project. Apparently the Chinese have revived it, as well.